# We sell plastic raw material # TPV TPE for Automotive

Company Profile

National enterprise group, founded in 1991, China‘s top 500 private enterprises,2020 turn over 4.9 billion USD, and subsidiary company Dawn Polymer turn over around 680 million USD. Dawn Polymer's product TPV TPE for automotive have made a significant contribution.

New start: Dawn Polymer successful listing on the stock market(6 th Jan.2017)

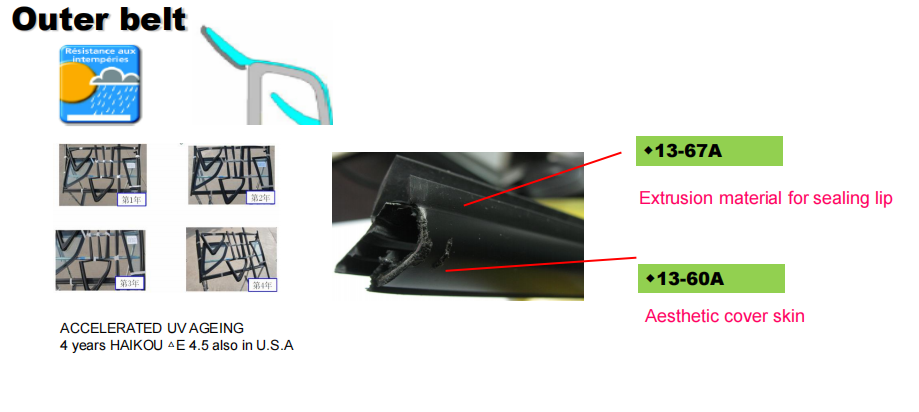

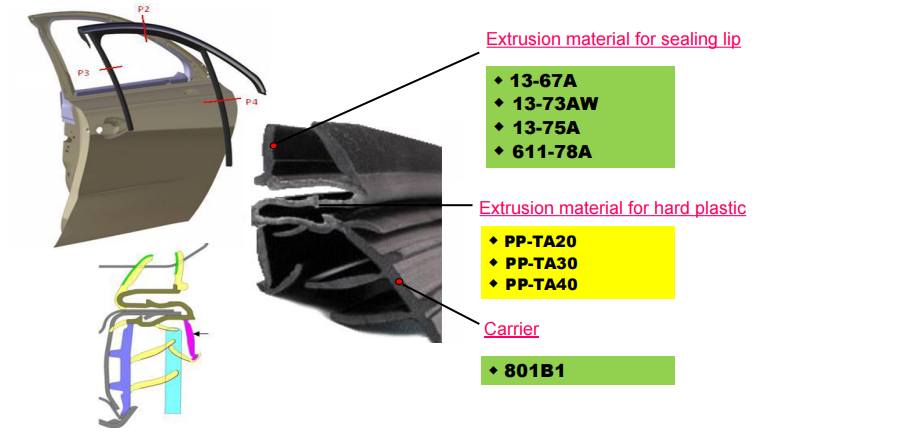

Auto Sealing System OEM Approved Grades & Applications

Below are details of TPV TPE for automotive application and grades for your reference.

If you need other plastic&rubber raw material, please transfer to our Product Page and find it!

Hot Tags: tpv tpe for automotive, China tpv tpe for automotive manufacturers, suppliers, factory