Polyethylene Raw Material

Polyethylene is a widely used polymer material in the world today. It is a thermoplastic polymer which can be produced in various grades, each with different physical properties. Polyethylene raw material is a grade of polyethylene which has excellent mechanical and chemical properties. In this article, we will explore what polyethylene raw material is, its properties, and why it is ideal for manufacturers who require low-cost, high-quality materials.

What is Polyethylene Raw Material?

Polyethylene raw material is an industrial material produced from polyethylene polymer. Polyethylene is produced by polymerization of ethylene gas. The polymerization process produces different grades of polyethylene with varying physical and chemical properties. Polyethylene raw material is a grade of polyethylene which has high density and excellent tensile strength.

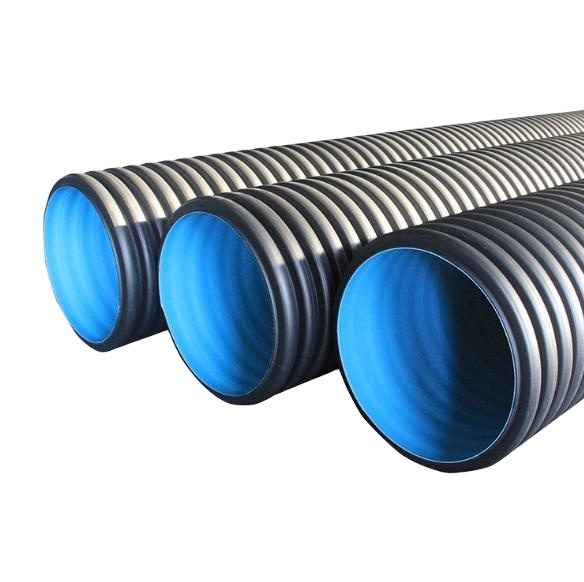

Polyethylene raw material can be used in various industrial sectors. It is used extensively in the production of plastic bags, packaging materials, and other disposable products. It is also used in the production of pipes, wire coatings, and other industrial products where high tensile strength is required.

Properties of Polyethylene Raw Material

Polyethylene raw material is an ideal material for manufacturing due to its unique properties. It has excellent mechanical properties, such as high tensile strength, high impact resistance, and toughness. It is also highly resistant to chemical attack, making it a widely used material in the chemical industry.

One of the most significant advantages of polyethylene raw material is its low cost. Polyethylene is a widely available material, and production costs are relatively low compared to other materials such as metal or ceramics. This makes the material an affordable choice for manufacturers who require high-quality materials at a lower cost.

Polyethylene raw material is also highly resistant to environmental factors such as ultraviolet (UV) radiation, moisture, and temperature changes. This makes it a suitable material for use in outdoor applications such as construction, marine, and agricultural industries.

Benefits of Polyethylene Raw Material

There are several benefits to using polyethylene raw material in manufacturing. One of the main advantages is its high durability, which makes it an ideal material for use in high wear and tear environments. The material has excellent resistance to impact, abrasion, and puncture, which ensures a long service life.

Polyethylene raw material is also highly resistant to chemicals, oils, and solvents. This makes it a suitable material for use in the chemical and petroleum industries, where materials must be highly resistant to corrosion and chemical attack.

Another significant advantage of polyethylene raw material is its relatively low cost compared to other materials. It is a widely available material, and the production cost is relatively low. This ensures that manufacturers can produce high-quality goods at lower costs, thereby maximizing their profitability.

Conclusion

Polyethylene raw material is an ideal material for a wide range of industrial applications. Its unique properties, low cost, and durability make it a highly suitable material for manufacturing. Whether you are in the packaging, construction, or chemical industry, polyethylene raw material offers a wide range of benefits and advantages. As a manufacturer located in China, we can offer high-quality polyethylene raw material at an affordable price. Our production capabilities are highly efficient, and we are committed to providing excellent customer service. Contact us today to learn more about our products and how we can help you grow your business.

Products Description

Polyethylene (polyethylene , abbreviated as PE) raw material is divided into linear polyethylene (POE, ULDPE, VLDPE, LLDPE, mDPE, MDPE, HDPE and UHMWPE) and branched polyethylene (LDPE, EVA, EVOH, EEA, etc.) according to the structure of the polymer chain.

Polyethylene raw material usually divided into high density polyethylene (HDPE), medium density polyethylene (MDPE), low density polyethylene (LDPE), and linear low density polyethylene (LLDPE) according to density.

The main parameters of polyethylene are density and melt index. Density characterizes the tightness between the long main chains of the polymer and the regularity (or crystallinity) of the structure; melt index characterizes the relative molecular weight of the polymer.

Products Classification

High-density polyethylene (HDPE), commonly known as low-pressure polyethylene, has a density of 0.941-0.96g/cm3 and a melting point of 131-137°C. It has high temperature resistance, oil resistance, steam permeability resistance and environmental stress cracking resistance, excellent electrical insulation, impact resistance and cold resistance, and is mainly used for blow molding, injection molding, extrusion of pipes, films, profiles and rotomolding of large blow molding products.

Low density polyethylene (LDPE) is commonly known as high pressure polyethylene, the irregularity of the branched chain structure makes LDPE less crystalline, with a low density of 0.910-0.925g/cm3 and a melting point of 105-115°C. It has good flexibility, extensibility and transparency, and is mainly used in the production of plastic bags, agricultural films, etc.

Linear low density polyethylene (LLDPE), is a copolymer of ethylene and a small number of 1-olefins such as 1-butene, 1-hexene and 1-octene, copolymer monomer content of 8%-10%, its molecular chain does not exist long branches, has a narrower molecular weight distribution, density of 0.910-0.925g/cm3, melting point 122-124 ℃. LLDPE high crystallinity, slightly less transparent, with low temperature LLDPE's largest application area is film, producing films with higher puncture resistance and strength. It has penetrated most LDPE applications, such as food bags, agricultural films, geomembranes, injection molded closures, various containers, paint cans, rotomolded drums and other blow molding products.

If you need other plastic&rubber raw material, please transfer to our Product Page and fnd it!

Why choose us?

- We are a Chinese factory specializing in high-quality plastic raw materials and professional services.

- Our company is in a critical period of transformation and upgrading, in order to move towards the benchmark of becoming stronger, better and bigger, and to build a "century-old store", we must bury our heads in hard work, hard work, hard work, hard work.

- We provide professional packaging and shipping services for plastic raw materials.

- Our company is willing to provide new and old customers with high quality Polyethylene Raw Material and satisfactory service.

- We are committed to providing excellent customer service and support.

- Our communication philosophy is that honesty is effective.

- With our strong supply chain, we can ensure timely delivery of plastic raw materials.

- Strategy is the foundation of an enterprise's success. It is a plan, which can integrate the enterprise's goals and policies, and make the enterprise put into action consistently.

- We offer technical assistance and training to customers in the use of plastic raw materials.

- Our company has accumulated rich production experience, using advanced equipment, high-standard materials and fine craftsmanship to continuously improve product quality and strive to achieve zero defects in product quality.

Hot Tags: polyethylene raw material, China polyethylene raw material manufacturers, suppliers, factory