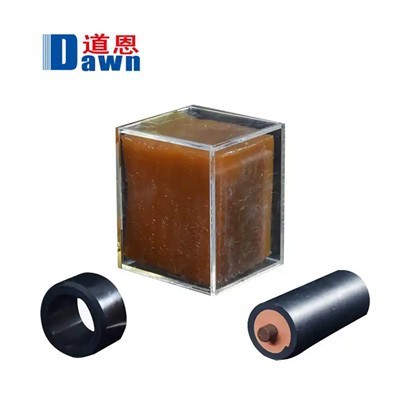

HNBR aramid fiber seals are high-performance sealing products that are widely used in various industries, including automotive, aerospace, oil and gas, and marine. These seals are made from a combination of hydrogenated nitrile-butadiene rubber (HNBR) and aramid fibers, which provide excellent resistance against wear, friction, and high temperatures.

The exceptional properties of HNBR aramid fiber seals make them suitable for various applications, such as sealing high-pressure hydraulic systems, compressors, pumps, and engines. These seals are also used in the aerospace industry, where they help maintain the pressure levels in aircraft fuel systems and hydraulic systems. Moreover, the oil and gas industry employs these seals for various components, including pipeline flanges, valves, and fittings.

One of the major advantages of HNBR aramid fiber seals is their ability to withstand extreme temperatures and pressure. These seals can resist temperatures ranging from -40°C to 200°C, making them ideal for use in hot and cold environments. Additionally, they can withstand high-pressure hydraulic systems that operate at pressures up to 700 Bar.

HNBR aramid fiber seals offer excellent chemical resistance, with resistance to oils, fuels, and chemicals commonly used in industrial applications. Their durable and flexible nature also allows them to adapt to fluids of different viscosity, further enhancing their reliability.

In conclusion, HNBR aramid fiber seals are essential components in various industries, thanks to their exceptional properties. These seals provide optimal sealing performance, ensuring efficient and reliable operation of vital systems and equipment.

Hot Tags: hnbr aramid fiber seal, China hnbr aramid fiber seal manufacturers, suppliers, factory, hdpe 400, fabric spunbond, Polypropylene Impact Copolymer, non woven fabric with adhesive, tpe e tpu, automotive nonwovens