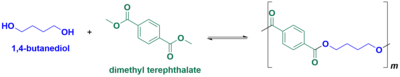

PBAT is synthesized from the polymer of 1,4-butanediol and adipic acid and the polymer of dimethyl terephthalate (DMT) with 1,4-butanediol.

Adipic acid and 1,4-butanediol are polymerized to create their polyester (plus water). DMT and 1,4-butanediol are also reacted to form their polyester (plus methanol). This polyester is then added to the butylene adipic acid polyester by using tetrabutoxytitanium (TBOT) as a transesterification catalyst; an overabundance of 1,4-butanediol influences chain lengths. The result is a copolymer of the two previously prepared polymers.

The polyester of DMT is generated using 1,4-butanediol. This is the second polymer used with the step 1 product to create the copolymer PBAT.

TBOT is used to catalyze the transesterification of the polyesters of adipic acid and DMT to generate the random, copolymer PBAT.

This is a random copolymer, because there is no control on the dispersity of the polymer chain lengths or block structuring in the copolymerization reactions; repeat positions are not controlled. If A = polyester of adipic acid and B = polyester of DMT, each with 1,4-butanediol, then the chain structuring could look like any of these: AABABBABA or ABABAAAABB or ABABABBBBA; there is no selectivity for A and B reacting with themselves or each other.[8]

Hot Tags: 100 biodegradable pbat resin for blowing film, China 100 biodegradable pbat resin for blowing film manufacturers, suppliers, factory