Introduction

Welcome to the world of Dawn Brand HNBR Grades – a high-quality product that is designed to meet the needs of businesses across industries. As a manufacturer based in China, our focus has always been to deliver exceptional products that cater to the diverse needs of our customers.

In this guide, we will take a closer look at our HNBR grades and how they can benefit your business. We will delve into the technical details of the product, explore the applications and industries that it is suited for, and also touch on some of the key features that set Dawn Brand HNBR grades apart from other products in the market.

What are HNBR Grades?

HNBR stands for Hydrogenated Nitrile Butadiene Rubber – a synthetic elastomer that is known for its excellent resistance to heat, oil, and chemicals. HNBR is a modified version of NBR rubber, which is a popular material used in sealing and gasket applications.

HNBR grades are categorized based on their acrylonitrile (ACN) content, which can vary from 18% to 50%. Higher ACN content results in better resistance to oil and chemicals, while lower ACN content yields better low-temperature flexibility.

Dawn Brand HNBR Grades

At Dawn Brand, we offer a range of HNBR grades that are engineered to meet the needs of different industries and applications. Our HNBR grades are formulated using the latest technology and are subject to rigorous quality control checks to ensure that they meet international standards.

Here are some of the key features of our HNBR grades:

1. Excellent resistance to heat and chemicals

Our HNBR grades have outstanding resistance to heat and chemicals, making them an ideal choice for use in harsh environments. They can withstand temperatures ranging from -40°C to 150°C and can resist a variety of chemicals, including acids, fuels, and oils.

2. High tensile strength and abrasion resistance

Our HNBR grades have a high tensile strength and abrasion resistance, which makes them suitable for use in dynamic sealing applications. They can withstand heavy loads and wear and tear, while maintaining their sealing properties.

3. Good ozone and weather resistance

Our HNBR grades have good ozone and weather resistance, making them suitable for use in outdoor applications. They can resist the effects of UV radiation, ozone, and other environmental factors, ensuring long-lasting performance.

Applications

Dawn Brand HNBR grades are used in a variety of industries and applications, including:

1. Automotive

Our HNBR grades are widely used in the automotive industry for applications such as engine sealing, fuel systems, and power steering. They can withstand the high temperatures and chemical exposure associated with these applications, ensuring reliable performance.

2. Oil and Gas

Our HNBR grades are also used in the oil and gas industry for applications such as sealing, gaskets, and o-rings. They can resist the effects of oil, gas, and other chemicals that are present in these environments.

3. Aerospace

Our HNBR grades are used in the aerospace industry for applications such as sealing, gaskets, and o-rings. They can withstand the extreme temperatures and pressures associated with aerospace applications, ensuring reliable performance.

Conclusion

Dawn Brand HNBR grades are a high-quality product that is engineered to meet the needs of businesses across industries. Our products are designed to withstand harsh environments and resist the effects of heat, chemicals, and weather.

With a range of grades available, we can cater to the diverse needs of our customers and provide them with the right solution for their application. If you are looking for a reliable and durable elastomer for your sealing or gasket needs, look no further than Dawn Brand HNBR grades.

Dawn Brand HNBR Grades

Dawn Brand HNBR Grades

DN3408

Acrylonitrile content(±1.5): 34%

Menney viscosity(±5): 70-80

Iodine value: 4-10

Characteristics and applications: High saturation grade, suitable for peroxide vulcanization, excellent heat resistance, suitable for timing belts, multi-vane belts, O-rings, gaskets and seals, etc.

DN3418

Acrylonitrile content (±1.5): 34%

Menney viscosity(±5): 70-85

Iodine value: 10-22

Characteristics and applications: Standard medium to high nitrile grade with excellent dynamic and processing properties, suitable for timing belts, O-rings, gaskets, oil seals and oil industry parts, etc.

DN3428

Acrylonitrile content(±1.5): 34%

Menney viscosity(±5): 70-85

Iodine value: 22-40

Characteristics and Uses: Low saturation grade, sulfur vulcanized to provide excellent dynamic properties for rotary oil seals, rubber rollers and dynamic oilfield components, etc.

DN3405

Acrylonitrile content(±1.5): 34%

Menney viscosity(±5): 50-60

Iodine value: 4-10

Characteristics and applications: Low to medium Menny grade, excellent processability

# Dawn Brand HNBR Grades

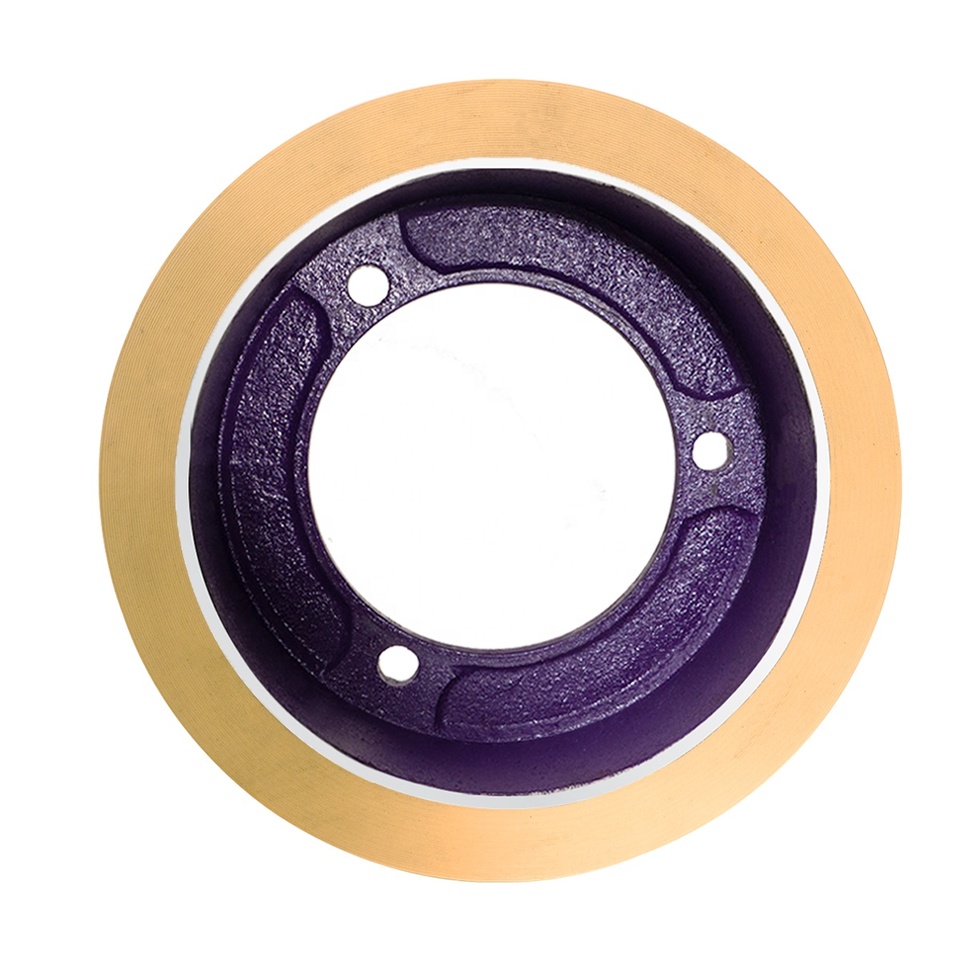

Compounding Rubber

A8001 Good high and low temperature performance and pressure change performance, excellent refrigerant resistance, can enhance the service life of the product, widely used in car air conditioners, home air conditioners and other related fields, can customize the production of different hardness of the compounding rubber.

A7501 Excellent oil and heat resistance, high tearing performance, good dynamic performance, able to be used in water and oil environment for a long time.

A6002 Capable of long-term use in the oilfield, excellent wear resistance and able to withstand 150°C high temperature.

A6801 It can be used in water and oil environment for a long time, can withstand 80MPa pressure, has excellent oil and heat resistance, high tensile strength, low pressure change.

# Dawn Brand HNBR Grades

If you need other plastic&rubber raw material, please transfer to our Product Page and find it!

Why choose us?

- Our HNBR products are suitable for use in soft and hard seals, gaskets, and other applications.

- We take credit establishment as the foundation of enterprise development, operate according to the law, standardize operation, and establish a good brand image for the enterprise.

- We take pride in providing our clients with the best quality HNBR products and services.

- Our brand culture has become an effective means and spiritual power to promote our business performance and economic growth.

- We have a wide range of HNBR products in stock for fast delivery.

- Your development is our progress, we have high-quality Dawn Brand HNBR Grades, superb technology, value-added performance and price ratio.

- Our HNBR products meet or exceed industry standards and specifications.

- We promote energy conservation and environmental protection, continuously strengthen technical research, deepen scientific and technological innovation, and reduce resource waste.

- We offer flexible customization options for our HNBR products.

- Adhere to the group's interests, the overall situation, cooperation and partnership. To be responsible, first of all, we should dare to take responsibility. Only those who dare to take responsibility and dare to rush forward can be respected and achieve greater development.

Hot Tags: dawn brand hnbr grades, China dawn brand hnbr grades manufacturers, suppliers, factory